Quick-Pipe Compressed Air Pipe DN 20 ~ DN 200 OEM Customizing Compressor Part Pipe

Benefits of Quick-Pipe compressed air pipe: Installs faster than other common piping No specialized trades needed No thr;

Basic Info

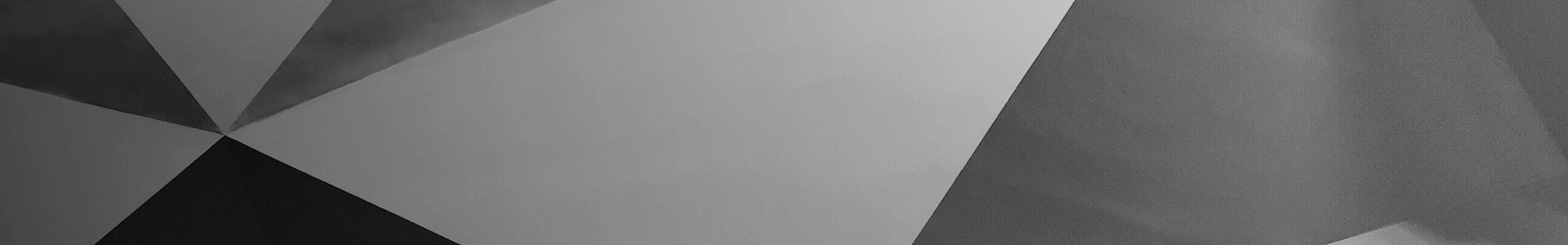

| Model NO. | 1-1/2 inch DN65 |

| Plastic Composite Pipe Coating Form | Inner and Outside Coating |

| Plastic Composite Pipe Model | GS-—X-SP-T-EP |

| Steel Skeleton PE Pipe Use | Oil Pipeline |

| Aluminium Plastic Compound Pipe Use | Water Distribution Pipe in Building |

| Steel Plastic Composite Pipe Model | GS-—X-SP-T-EP |

| Aluminium Plastic Compound Pipe Material | Crosslinked Polyethylene Aluminum Composite Pipe |

| Mode Diameter | DN 80, DN100 DN 125, DN 150, DN 200 |

| Length for Each Piece | 3000mm & 6000mm |

| Suitable | Industrial Compressed Air Pipe |

| Material Environmental | 100% Recyclable |

| Connection Type | Socket |

| Tube Color Selection | Blue,/ Yellow/ Gray / Customizing |

| Leakage | No Leakage |

| Cross-Section Shape | Round |

| Advantages | Seamless Extruded Aluminum Tube |

| Working Pressure | 4bar, 5bar, 7bar, 8bar, 10bar, 12bar, 16bar |

| Standard | GB/T4437.1-2000 |

| Applicable Temperature | -30~+80c |

| Application 1 | Compressed Air Gas, Vacuum and Nitrogen Fluid |

| Connection Part | Reducing Pipe to Pipe Connector |

| Good for User | No Threading, Welding, or Brazing Pipe |

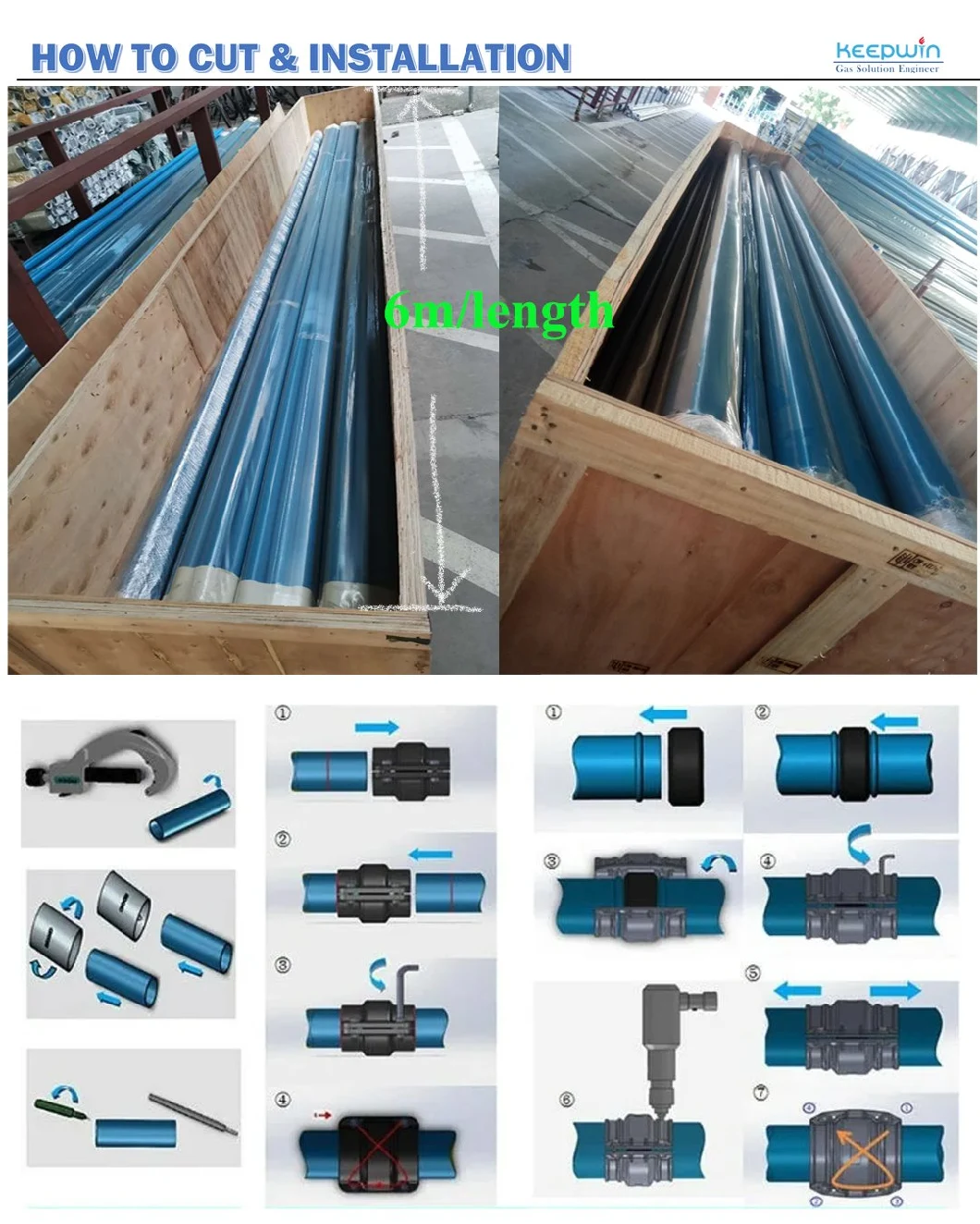

| Transport Package | Carton or Wooden Package |

| Specification | 6000* DN80*DN80mm |

| Trademark | KEEPWIN |

| Origin | China |

| HS Code | 76090000 |

| Production Capacity | 20000sets/Month |

Product Description

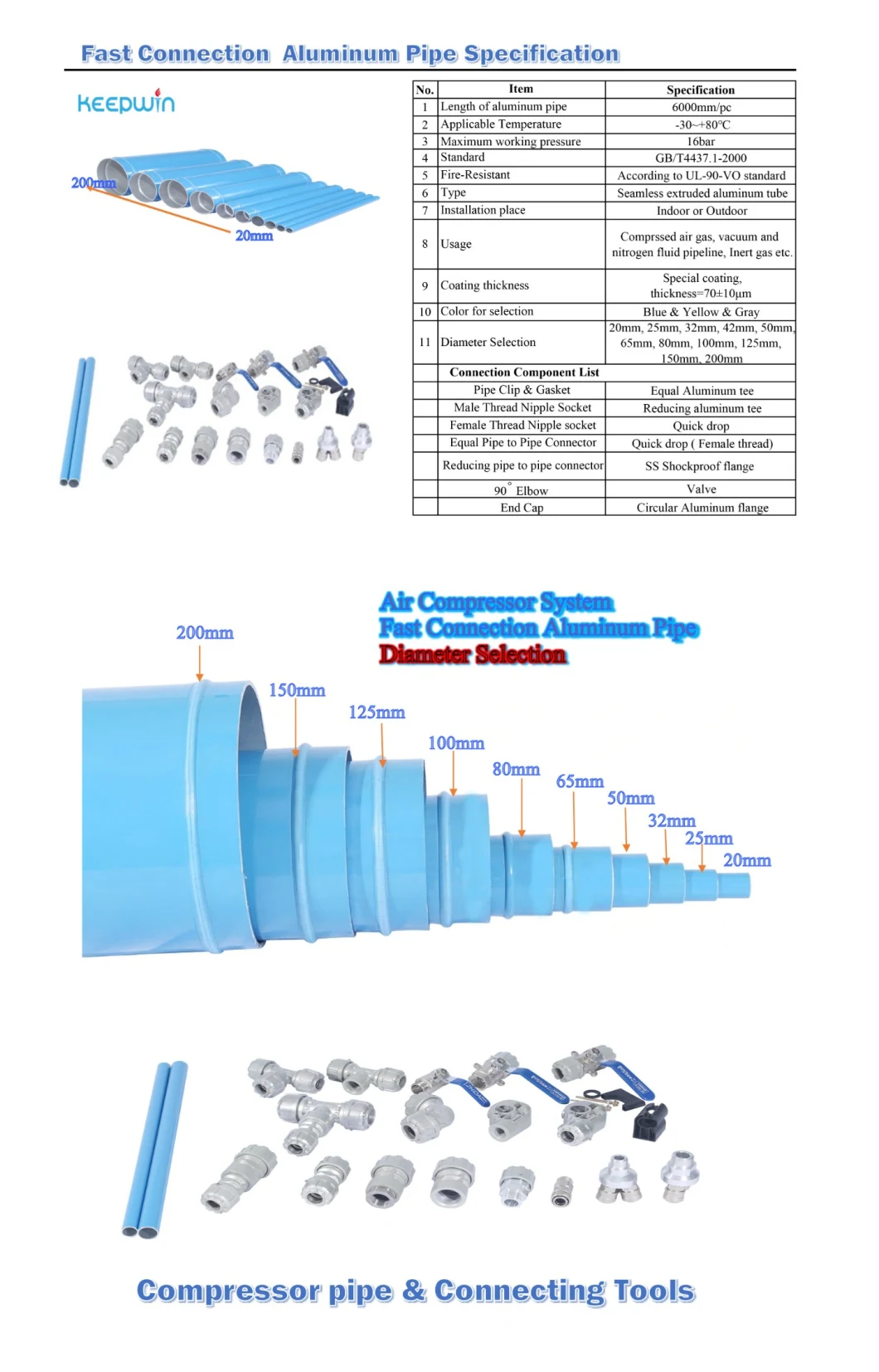

Benefits of Quick-Pipe compressed air pipe:- Installs faster than other common piping

- No specialized trades needed

- No threading, welding, or brazing pipe

- Simple mounting and connecting hardware

- Can connect to existing systems with other pipe types

- Easy to add on to or disassemble for your changing needs

- Compression style valves and fittings 2 1/2" and below

- Bolt-on style fittings 3" and above

- 10-year warranty

| MAX PRESSURE | 16BAR |

| WORKING TEMPERATURE RANGE | -29˚C~+80˚C |

| Main Material | Ductility aluminum alloy 6063(GB/T 4437.1-2015) |

| Specific Weight | 2.70 Kg/dm3 |

| External Coating / Internal Coating | Epoxy Polyester Powder / Chemically Anodized Treated |

| FIRE RESISTANCE | Fireproof and Suitable for Outdoor Applications |

| COMPATIBLE FLUIDS | Compressed air, vacuum, inert gas(AZOTO, ARGON, NITROGEN) |

Aluminum Alloy Pipe's Technical Parameters

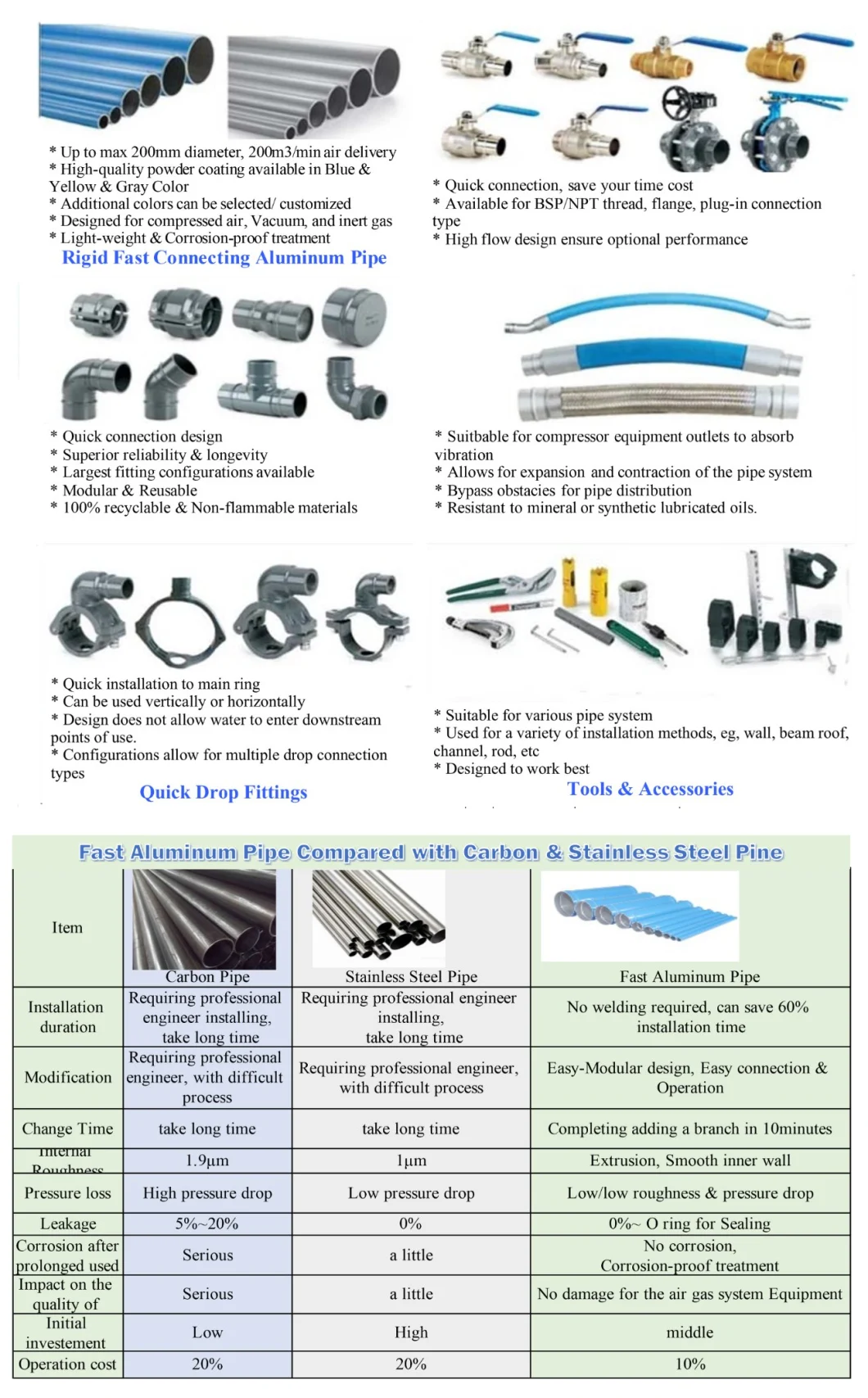

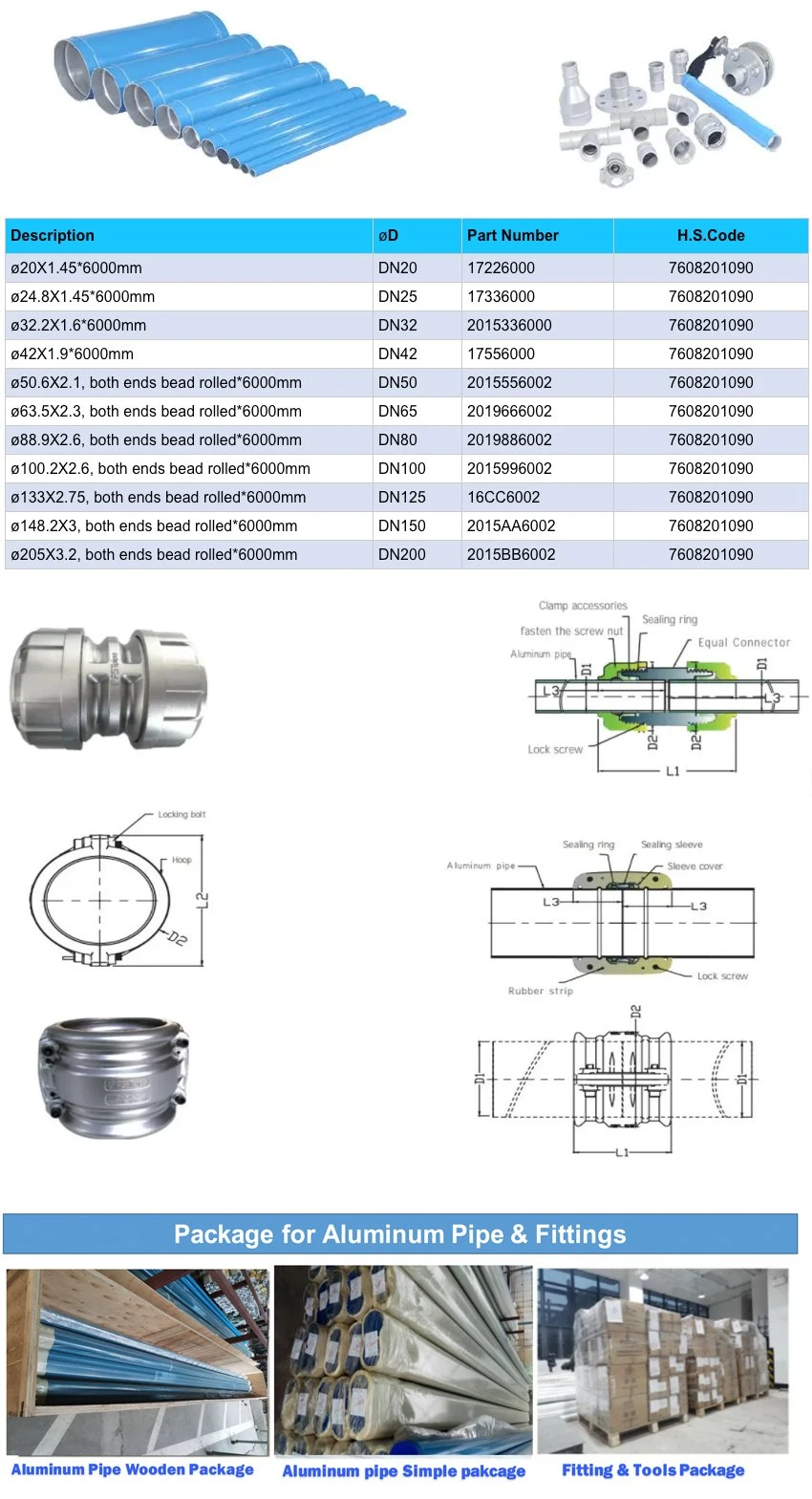

| No. | Part Name | øD mm | Part Number | Description |

| 1 | BlueYellowGrayAluminum Pipe | 20 | 17226000 | ø20X1.45*6000mm |

| 2 | 25 | 17336000 | ø24.8X1.45*6000mm | |

| 3 | 32 | 2015336000 | ø32.2X1.6*6000mm | |

| 4 | 42 | 17556000 | ø42X1.9*6000mm | |

| 5 | 50 | 2015556002 | ø50.6X2.1, both ends Bead rolled*6000mm | |

| 6 | 65 | 2019666002 | ø63.5X2.3, both ends Bead rolled*6000mm | |

| 7 | 80 | 2019886002 | ø88.9X2.6, both ends Bead rolled*6000mm | |

| 8 | 100 | 2015996002 | ø100.2X2.6, both ends Bead rolled*6000mm | |

| 9 | 125 | 16CC6002 | ø133X2.75, both ends Bead rolled*6000mm | |

| 10 | 150 | 2015AA6002 | ø148.2X3, both ends Bead rolled*6000mm | |

| 11 | 200 | 2015BB6002 | ø205X3.2, both ends Bead rolled*6000mm |

The Fast Connection Aluminium Pipe System segmented design also has the advantage of quick installation.

Installation is reduced by up to 50% when compared with traditional airline systems, leading to a high-cost saving in labor. Being a mechanical system, it also has the advantage that each and every joint is to the same quality of sealing as promised by the manufacturer, and is not reliant on the physical finesse that can deteriorate as a project nears completion.

Cost Saving Quality

Fast Connection Aluminum Alloy Piping Systems use no plastic, period. Made with 100% metal, quick-fit and elevation are the most cost-effective system available. Non-corrosive push to connect or grooved connect systems are fully tested to ANSI standards and are the most advanced systems available. When Compared to your standard piping systems, Fast Connection Aluminum Alloy Piping are leak-free system that includes a warranty to back it.

Female Threaded Nipple Socket's Technical Parameters

| Female Threaded Nipple Socket | 20×1/2" | 16201100 | Aluminum Alloy, one side Push in fit, the other side female threaded | 76090000 |

| Female Threaded Nipple Socket | 20×3/4" | 16211100 | Aluminum Alloy, one side Push in fit, the other side female threaded | 76090000 |

| Female Threaded Nipple Socket | 25×1/2" | 16301100 | Aluminum Alloy, one side Push in fit, the other side female threaded | 76090000 |

| Female Threaded Nipple Socket | 25×3/4" | 16311100 | Aluminum Alloy, one side Push in fit, the other side female threaded | 76090000 |

| Female Threaded Nipple Socket | 25×1" | 16321100 | Aluminum Alloy, one side Push in fit, the other side female threaded | 76090000 |

| Female Threaded Nipple Socket | 32×3/4" | 16411100 | Aluminum Alloy, one side Push in fit, the other side female threaded | 76090000 |

| Female Threaded Nipple Socket | 32×1" | 16421100 | Aluminum Alloy, one side Push in fit, the other side female threaded | 76090000 |

| Female Threaded Nipple Socket | 32×1"1/4" | 16431100 | Aluminum Alloy, one side Push in fit, the other side female threaded | 76090000 |

| Female Threaded Nipple Socket | 42×1" | 16521100 | Aluminum Alloy, one side Push in fit, the other side female threaded | 76090000 |

| Female Threaded Nipple Socket | 42×1"1/4" | 16531100 | Aluminum Alloy, one side Push in fit, the other side female threaded | 76090000 |

| Female Threaded Nipple Socket | 42×1"1/2" | 16541100 | Aluminum Alloy, one side Push in fit, the other side female threaded | 76090000 |

| Female Threaded Nipple Socket | 42×2" | 16551100 | Aluminum Alloy, one side Push in fit, the other side female threaded | 76090000 |

| Female Threaded Nipple Socket | 50×1"1/2" | 2019541100 | Aluminum Alloy, one side Push in fit, the other side need to match 1 set of 50mm Clamp | 76090000 |

| Female Threaded Nipple Socket | 50×2" | 2019551100 | Aluminum Alloy, one side Push in fit, the other side need to match 1 set of 50mm Clamp | 76090000 |

| Female Threaded Nipple Socket | 65×2"1/2" | 2019661100 | Aluminum Alloy, one side Push in fit, the other side need to match 1 set of 65mm Clamp | 76090000 |

| Female Threaded Nipple Socket | 80×3" | 2019881100 | Aluminum Alloy, one side Push in fit, the other side need to match 1 set of 80mm Clamp | 76090000 |

| Female Threaded Nipple Socket | 100×3" | 2015981100 | Aluminum Alloy, one side female threaded, the other side need to match 1 set of 100mm Clamp | 76090000 |

| Female Threaded Nipple Socket | 125×4" | F16C91100 | Aluminum Alloy, square female threaded Nipple Socket | 76090000 |

| Female Threaded Nipple Socket | 150×3" | 16A81100 | Aluminum Alloy, one side female threaded, the other side need to match 1 set of 150mm Clamp | 76090000 |

| Female Threaded Nipple Socket | 150×4" | 16A91100 | Aluminum Alloy, one side female threaded, the other side need to match 1 set of 150mm Clamp | 76090000 |

| Female Threaded Nipple Socket | 200×3" | 16B81100 | 200mm Clamp | 76090000 |

| Female Threaded Nipple Socket | 200×4" | 16B91100 | Aluminum Alloy, one side female threaded, the other side need to match 1 set of 200mm Clamp | 76090000 |

90° Elbow's Technical Parameters

| 90° Elbow | 20 | 16220300 | Push in fit, Aluminum Alloy | 76090000 |

| 90° Elbow | 25 | 16330300 | Push in fit, Aluminum Alloy | 76090000 |

| 90° Elbow | 32 | 16440300 | Push in fit, Aluminum Alloy | 76090000 |

| 90° Elbow | 42 | 16550300 | Push in fit, Aluminum Alloy | 76090000 |

| 90° Elbow | 50 | 2019550300 | Aluminum Alloy, need to match 2 sets of 50mm Clamp | 76090000 |

| 90° Elbow | 65 | 2019660300 | Aluminum Alloy, need to match 2 sets of 65mm Clamp | 76090000 |

| 90° Elbow | 80 | 2019880300 | Aluminum Alloy, need to match 2 sets of 80mm Clamp | 76090000 |

| 90° Elbow | 100 | 2015990300 | Aluminum Alloy, need to match 2 sets of 100mm Clamp | 76090000 |

| 90° Elbow | 125 | F16CC0300 | Aluminum alloy, suitable for bead rolled pipe | 76090000 |

| 90° Elbow | 150 | 2015AA0300 | Aluminum Alloy, need to match 2 sets of 150mm Clamp | 76090000 |

| 90° Elbow | 200 | 2015BB0300 | Aluminum Alloy, need to match 2 sets of 200mm Clamp | 76090000 |

You may also like

Send inquiry

Send now